Collection: 3M™ Abrasives

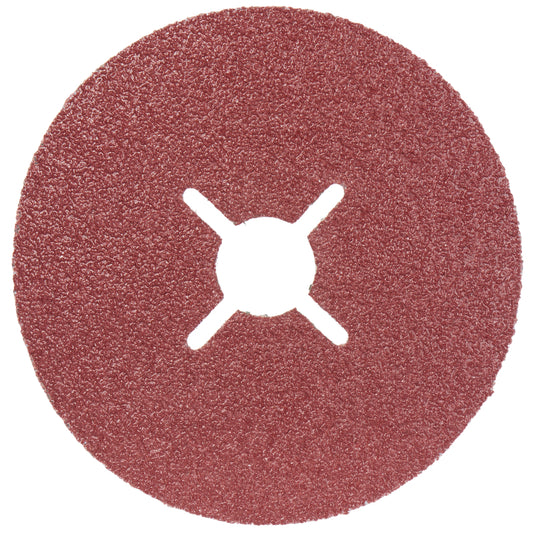

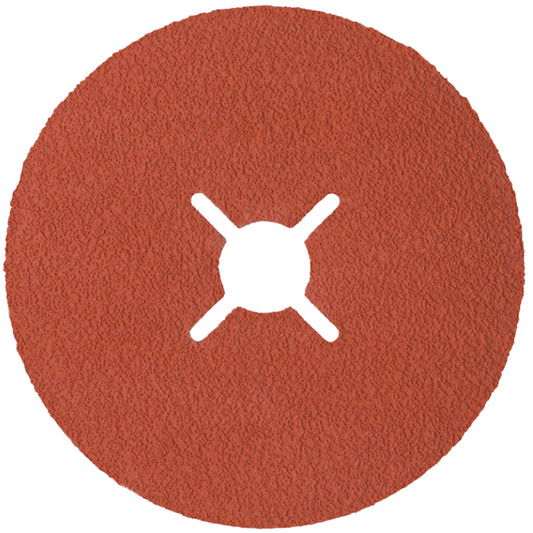

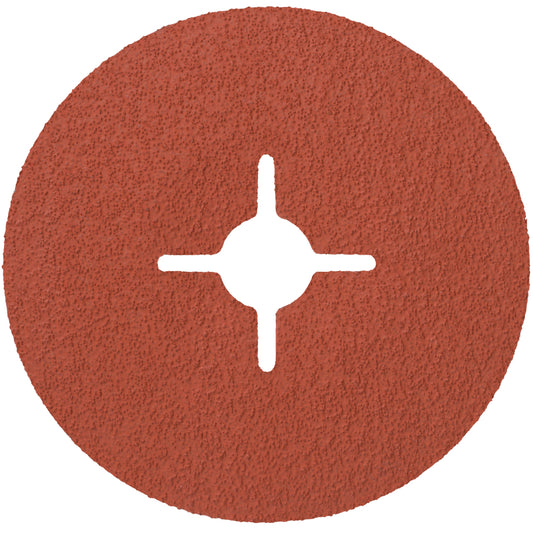

3M™ Cubitron™ 3 Fibre Discs

Breakthroughs in technology that are redefining the limits of cut rate and total stock removal, with a focus on prioritising productivity, safety, sustainability, and optimising automation.

A new era of abrasive performance is here.

Introducing 3M re-engineered Precision-Shaped Grain, boosting the speed and life of 3M™ Cubitron™ Performance Abrasives to new heights. This advancement prioritises operator safety, maximises sustainability, and amplifies time and labour efficiency.

Enhanced mineral orientation

-

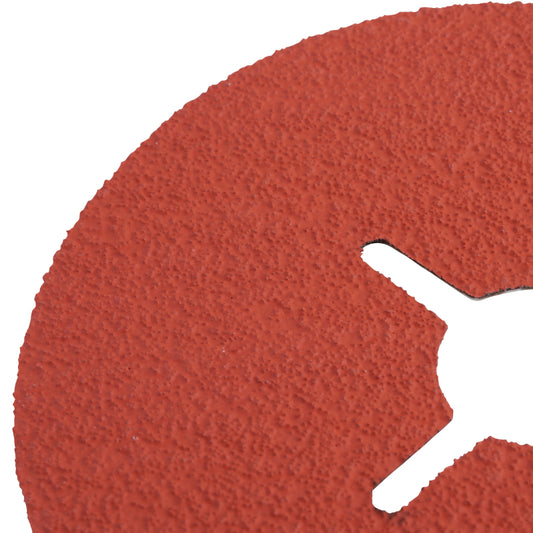

Latest 3M Precision-Shaped Grain

Re-engineered precision-shaped ceramic triangular grain using a proprietary breakthrough in grain shape. This helps increase productivity and lower overall grinding costs. - 3M Precision-Shaped Grain

3M pioneered the first precision-shaped grain using 3M microreplication technology to form consistent sharp peaks that easily “slice” through metal—cutting cooler, faster, and lasting longer than conventional abrasive grain.

- Conventional ceramic abrasive

Conventional ceramic abrasive grain tends to “plough” through metal, causing heat to build up in the workpiece and abrasive, resulting in a slower cut and shorter abrasive life compared to our latest precision-shaped grain.

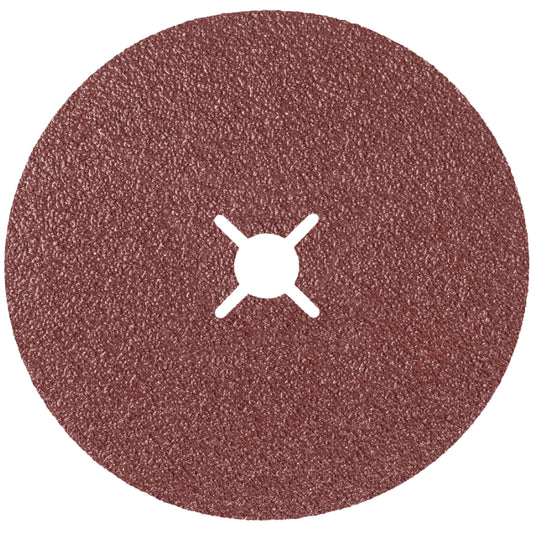

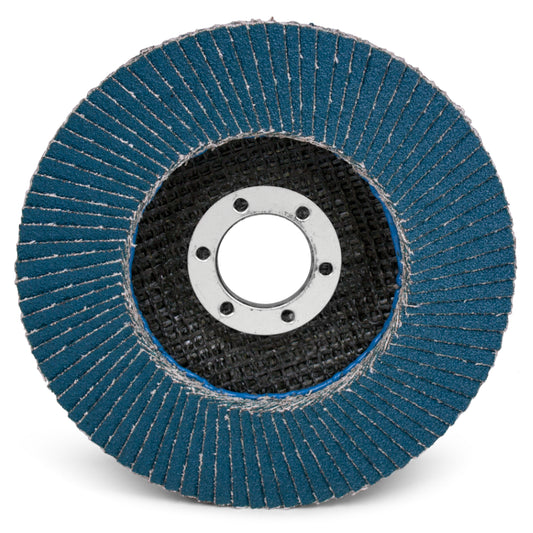

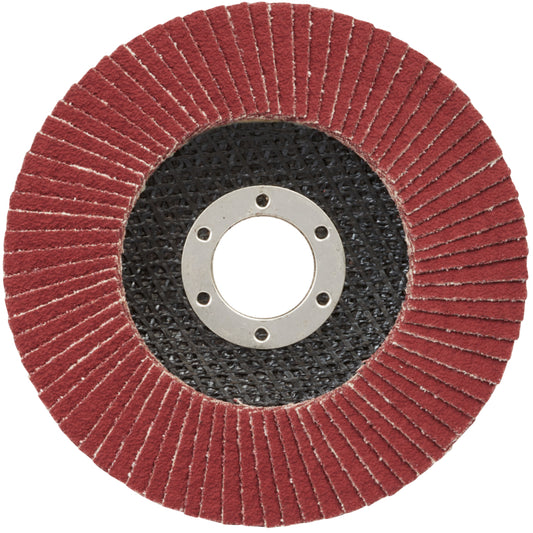

3M™ Cubitron™ II - Grinding and Cutting Reinvented

3M™ Cubitron™ II abrasives are revolutionising the cutting and grinding process. They’re faster cutting and longer lasting than conventional abrasives.

With 3M Precision-Shaped Grain technology that transforms the process of grinding and cutting metal, Cubitron™ II abrasives:

- Cut faster

- Stay sharp longer

- Require less pressure

- Held reduce operator fatigue

- Increase productivity

Conventional ceramic abrasive grain is irregular in shape. Instead of a clean, machining action, the grain ‘ploughs’ through the metal, causing heat build-up, slower cutting and shorter life.

3M Precision-Shaped Grain in Cubitron™ II abrasives continuously fracture to form sharp points and edges – slicing cleaner and faster, staying cooler and lasting many times longer.

3 reasons why its better

-

Cuts faster

helps improve productivity throughout -

Lasts longer

helps save money -

Easier to use

good for your workers, good for your business

3M™ Scotch-Brite™ - Prepared for perfection

The perfect finish starts with Scotch-Brite™

Performance. Durability. Reliability. Excellence. We don’t release a surface conditioning product until we can guarantee it delivers all four. Because at Scotch-Brite, our standards are as high as yours. After all, if you don’t compromise on quality, why should we?

Scotch-Brite Non-Woven Technology Explained

Our unique Non-Woven Web is the secret to superior performance. It binds together synthetic fibres and abrasive particles to create a conformable, three-dimensional material. Its open structure reduces the risk of warping or discolouring the part, resists loading, improves finish and prolongs the product’s life. What’s more, our Non-Woven Web is engineered to continually expose fresh abrasive to the work surface, for a consistent, smoother finish – without the risk of overworking the part and disturbing critical tolerances.

What makes Scotch-Brite the best you can buy?

- A tough, non-woven nylon web impregnated with resin and mineral throughout its structure.

- Spring-like action produces a smooth, burr-free surface.

- Uniform, consistent results with no undercutting.

- Suitable for deburring, finishing, cleaning and small weld removal applications.

- Easy to use, less rework, fewer rejects.

Read less

-

-

-

3M™ Cubitron™ 3 Depressed Centre Grinding Wheel 36+

Product Code: 99306

-

3M™ Cubitron™ II 1182C, 1187C & 982CX Pro Ribbed Back-up Pads

Product Code: 64860

-

-

-

-

-

-

-

-

-

-

-

-

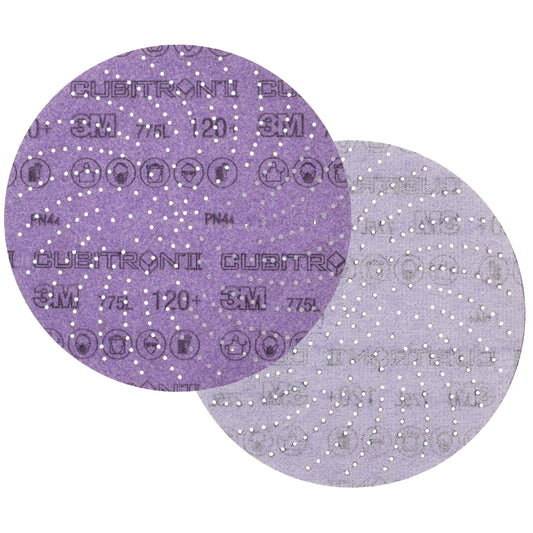

3M™ Cubitron™ II Hookit™ Sanding Disc 775L, 152 mm Diameter

Product Code: 86824

-

3M™ Cubitron™ II Hookit™ Sanding Film Disc 775L, 152 mm, No Hole

Product Code: 86820

-

-

3M™ Scotch-Brite™ Hookit™ Cut & Polish Disc 152mm No Hole A MED

Product Code: 60231

-

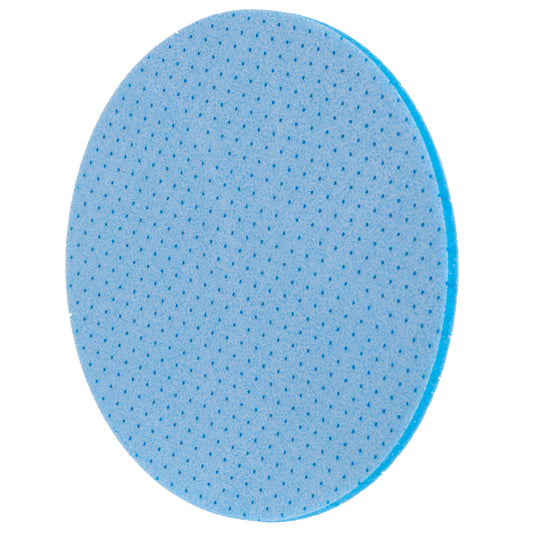

3M™ Hookit™ Flexible Abrasive Foam Disc P800 Grit 150mm

Product Code: 33540

-

-

-

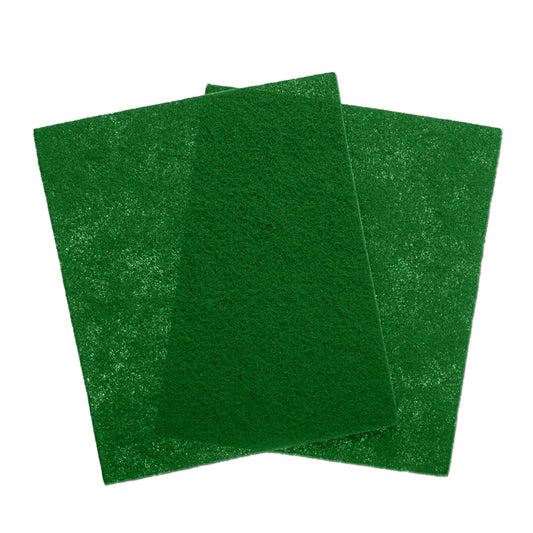

3M™ Scotch-Brite™ Light Green Hand Pad AFIN 158mm x 224mm

Product Code: 5305N

-